In-Road Digital Factory System

Focus on providing leading digital software and solutions for the chemical industry

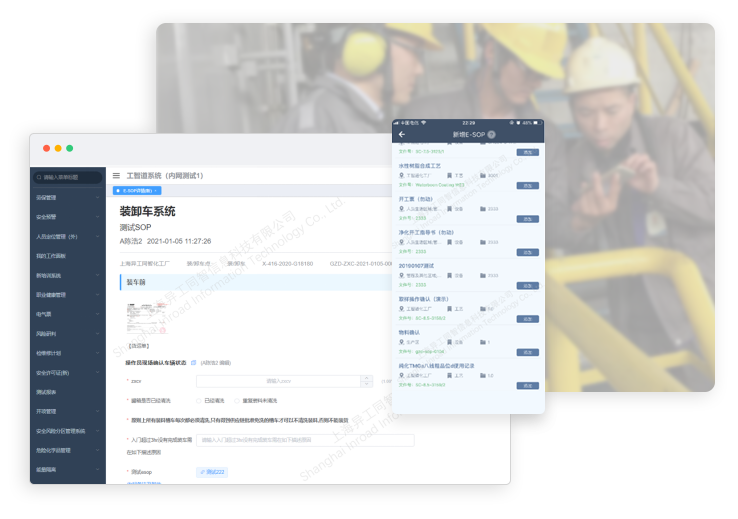

E-SOP management

E-SOP management

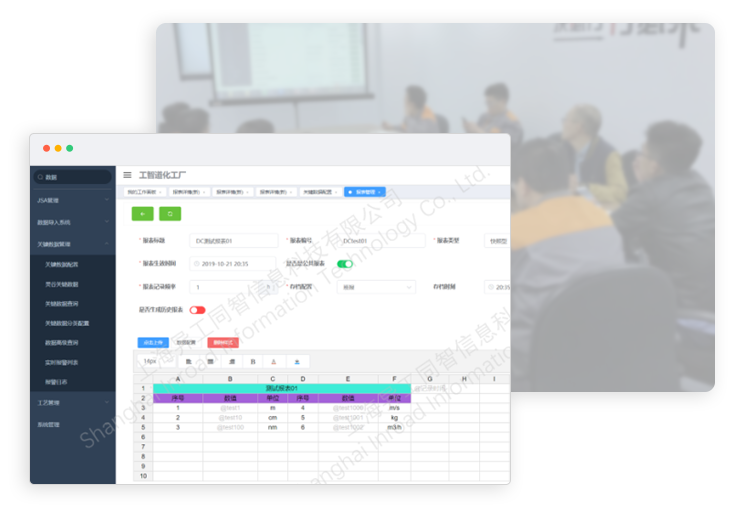

Management of inspection and maintenance items

Management of inspection and maintenance items

Operation data center

Operation data center

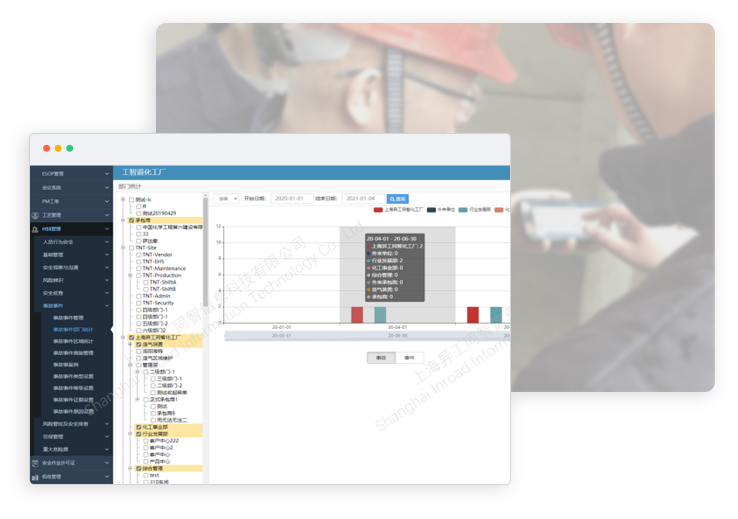

Accident management

Accident management

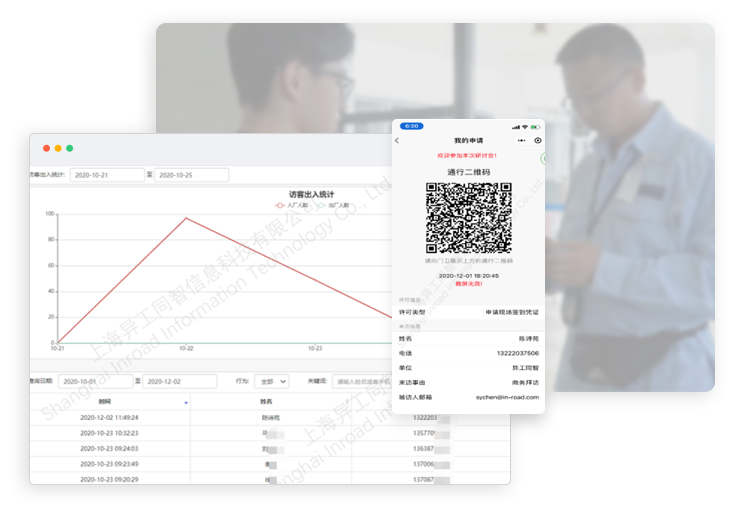

Smart visit management

Smart visit management