Technological leaps are essential for green and low-carbon transformation. China’s innovations in green and low-carbon technologies not only fuel its own sustainable development but also provide powerful, practical solutions for global sustainability.

Qing Feng Mao, a safety officer at the Environmental and Safety Department of Zhejiang Qu Hua Fluorochemical Co., Ltd.’s Fluoride Refrigerant Division, recently adopted a “new weapon” – an electronic work permit system.

“Now we no longer need to chase people across the site for signatures on construction permits, nor worry about forged, altered, or missing signatures due to unverified personnel qualifications. Through the mobile app, we can track real-time progress at every stage of a project,” Mao explained. “The electronic work permit system integrates decades of chemical industry experience, digitizes all critical information, and enables closed-loop management. Since its implementation, information flow efficiency has improved significantly.”

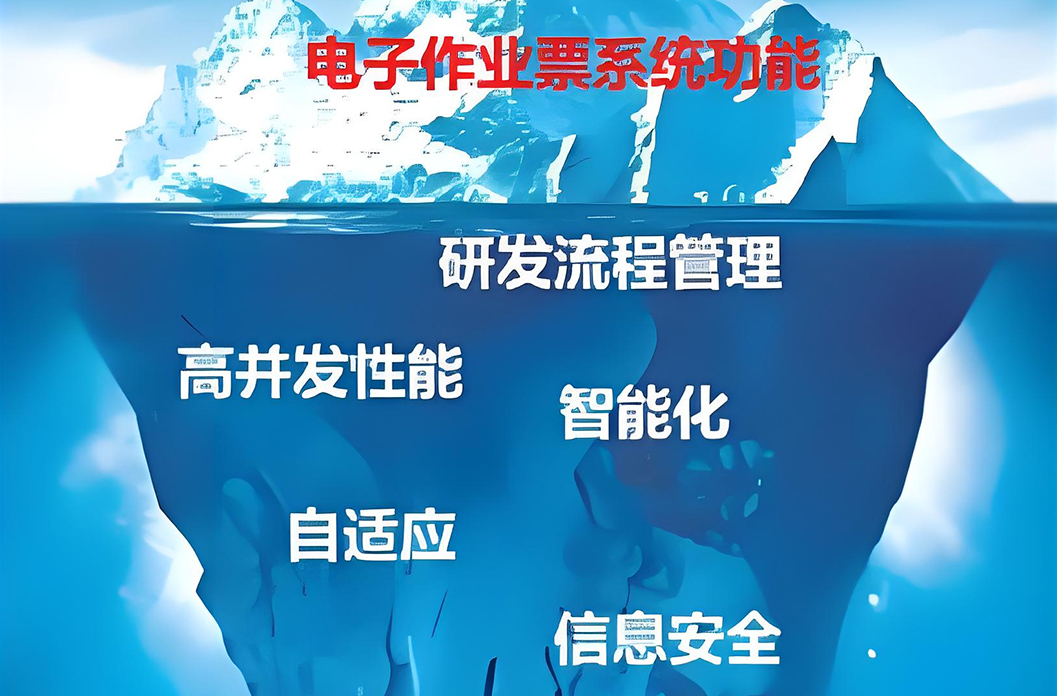

Chemical enterprises frequently require periodic or ad hoc maintenance, repairs, renovations, and construction. These non-routine activities carry higher accident risks compared to standard operations. “Traditional paper-based permits rely heavily on personnel experience for risk identification, making errors or omissions hard to avoid. In contrast, electronic permits standardize the entire lifecycle – from creation and approval to execution, supervision, closure, and analysis – with clear accountability,” said Jun Wu, Safety Director of Sinopec Yangzi Petrochemical Company. Yangzi Petrochemical has now fully adopted an online electronic work permit system. Leveraging 5G + industrial internet technologies, it replaces paper permits, streamlines process management, and boosts operational efficiency.

“Compared to steel or energy industries, the chemical sector represents a more complex form of process manufacturing, with intricate production workflows and diverse on-site management challenges. Every detail in the interconnected process chain impacts final outcomes,” Zhijie Zhou, CEO of In-Road. (referred to as “In-Road”), told Oriental Outlook Weekly.

A former professor at East China University of Science and Technology and alumnus of Fudan University’s Innovation and Entrepreneurship Program, Zhou brings unique insights into chemical R&D, production workflows, and enterprise management. “Traditional chemical manufacturing operated in siloed specialties like process engineering, equipment, and instrumentation – lacking ‘general practitioners’ for holistic oversight. But in the era of green transformation, chemical companies urgently need such ‘general practitioners’ for integrated process management,” Zhou emphasized. “As a digital solutions provider dedicated to the chemical industry, we innovate to make production safer, more stable, and higher quality.”

Hao Chen, In-Road’s Co-founder and COO, shared a case study: “A large chemical plant undergoes a 45- to 60-day overhaul every two years, involving over 10,000 daily workers. Our electronic permit system lets managers visualize every worker’s task, timelines, and progress via dashboards or mobile apps. It analyzes staffing efficiency, project feasibility, and schedule adherence.” He added, “For a project of this scale, using our system reduced the overhaul from 45 to 42 days – saving 30,000 man-days while enhancing safety. For a billion-dollar enterprise, each day saved translates to hundreds of millions in accelerated production – proving the immense value of green process innovation.”

Zhou further likened process management to human physiology: “Just as capillaries and nerve endings enable precise bodily functions, overlooked details in chemical workflows can accumulate risks. Our mission is to reinforce these ‘microscopic’ process elements using mobile internet technologies. For capital-intensive chemical plants, avoiding one accident through holistic management could save millions. “He also highlighted knowledge retention: “Veteran engineers carry invaluable tacit knowledge in their minds and habits. As they retire, our systems help codify this expertise into actionable protocols. Our tools may be feature-rich, but their core lies in intuitive design and high-frequency usability.”

Chen concluded, “While automation will replace repetitive tasks, human ingenuity remains irreplaceable. Our systems amplify the value of skilled labor by making complex workflows smarter and safer. Even as factory headcounts shrink, the remaining workforce will drive greater innovation.”

(Adapted from Oriental Outlook Weekly, Issue No. 926, 2025, originally titled “Greening the Future.”)